-

Anti Corrosion

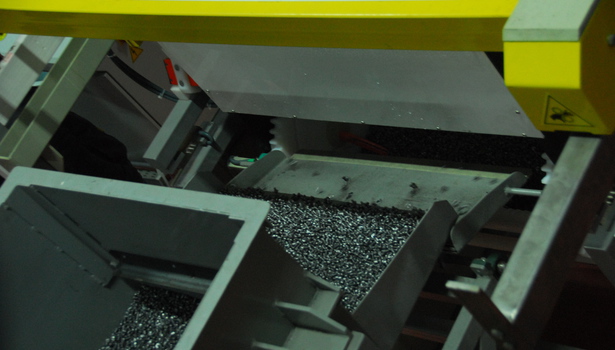

The most common electroplating application, the purpose is to increase metal products lifespan through the application of Zn and Zn alloys electro-deposition on the product surface. The process is either acidic or alkaline depending on the conditions and requirements specific to the product.

-

Decorative

Sometimes electroplating is done for shining. A thin layer of chrome element (Cr+6 or Cr+3, in other words, hexavalent or trivalent) in combination of various Ni depositions on the surface provides either bright chrome, colored chrome or matt (satin) chrome effect on the surface.

-

Functional

In order to gain some mechanical properties (e.g. Adhesion, less friction, hardness, etc.) some specific surface treatment operations may be performed on the base substance, like anodizing on aluminum, phosphating before coating, or hard chrome plating on hydraulic pistons... Bozkurt Plant Engineering will design the optimum equipment and/or automatic line for your specific requirement.

- PHONE +90 224 443 33 16

- MAIL info@bozkurt-pe.com

- English Español русский