-

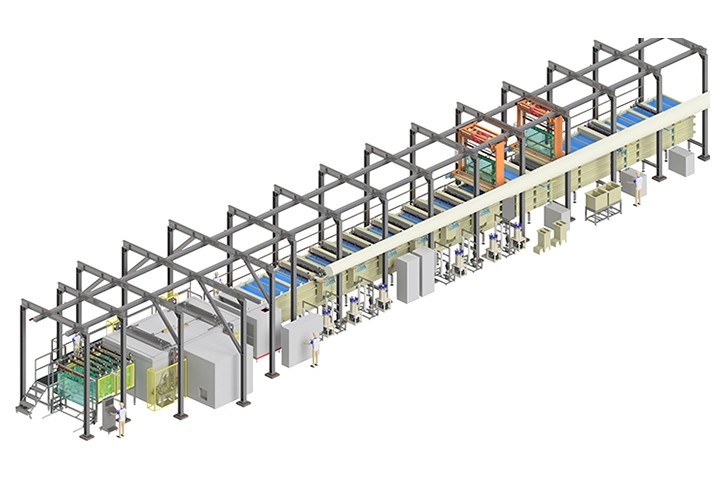

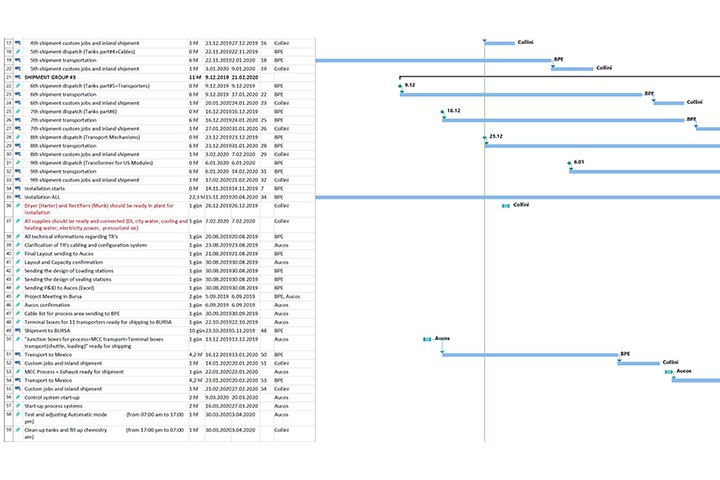

3D Detailed Design

Utilizing 3D CAD software, the complete system is designed virtually and validated, necessary before manufacturing operations.

-

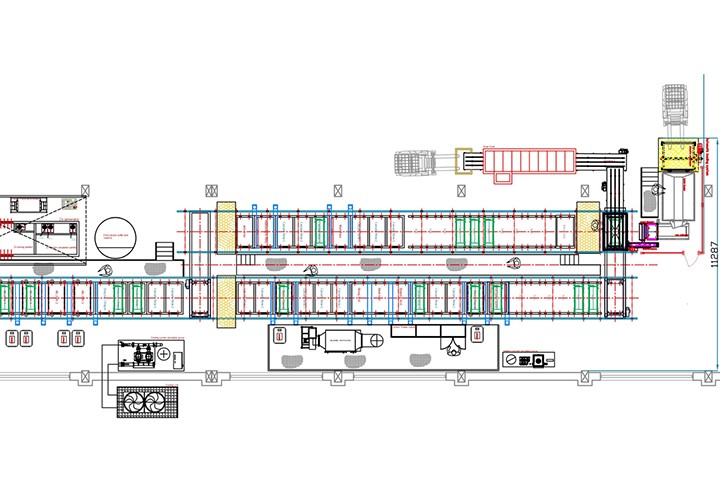

Concept Design

After receiving the initial data from the customer, the system is designed conceptually around the plating window concept for rack plating systems (and barrel size is defined in bulk plating systems). Afterwards the operations sequence and bottleneck operations are defined for capacity calculations. Introducing the customer's plant layout and material flow, the system design is completed with optimum layout for easier material handling and flow.

-

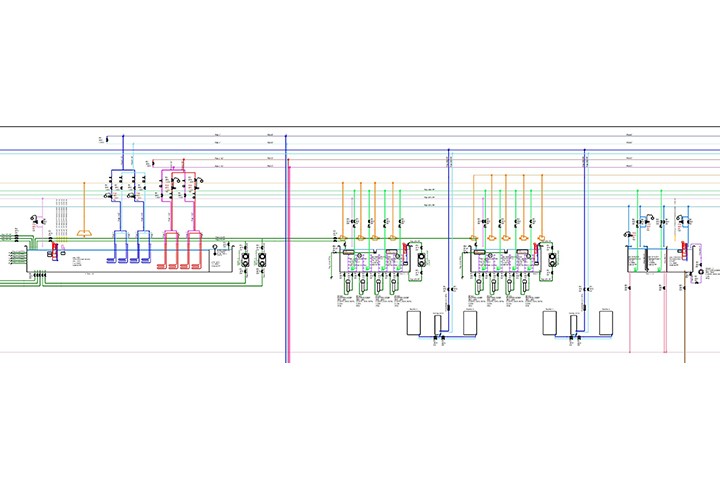

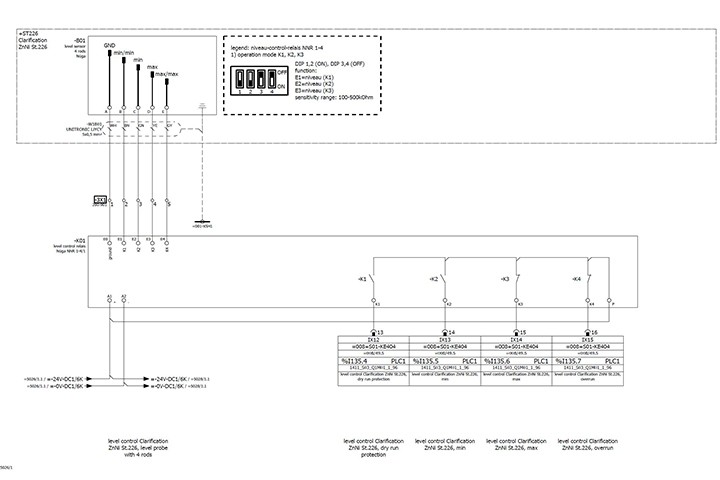

PID Design

P&ID (Process and Instrumentation diagram) is crucial for automatic systems design and communication between the parties, line builder, software designer, chemistry supplier and customer. It is the common platform for synchronization of all parties.

-

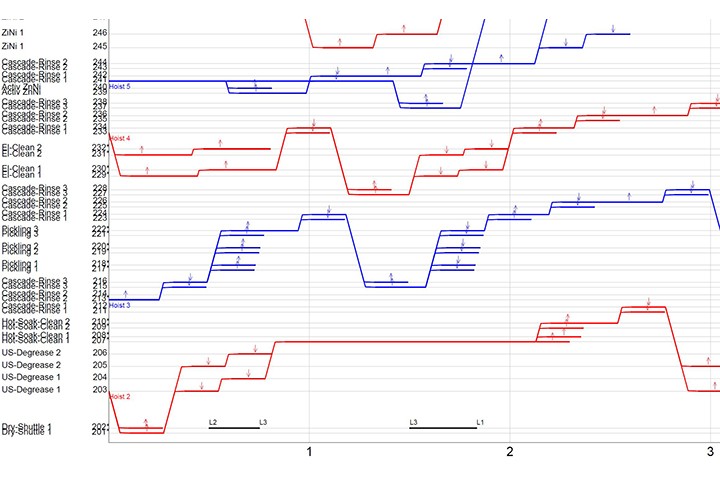

Simulation

For the capacity validation it is essential to perform simulation studies, which yields time/way diagram for the system demonstrating the transporters movement for steady state production. So it is guaranteed that the design will meet the capacity requirement.

-

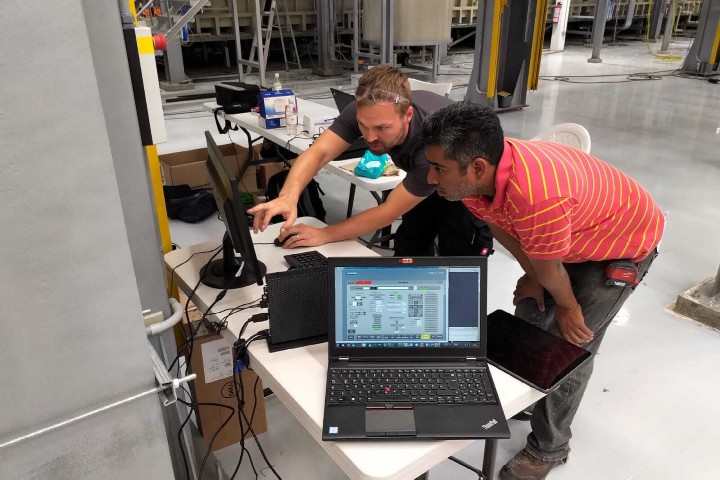

E-Plans & Electro Projects

Eplans and electro-projects

Complete system electrical engineering is done on e-plan basis in parallel with the PID. All electrical hardware installation is planned and performed accordingly.

- PHONE +90 224 443 33 16

- MAIL info@bozkurt-pe.com

- English Español русский